Introduction. Market Size and Growth. Market Segmentation. Competitive Landscape. Conclusion....

1. Regular Cleaning and Inspection. 2. Lubrication and Alignment. 3. Preventive Maintenance Schedule....

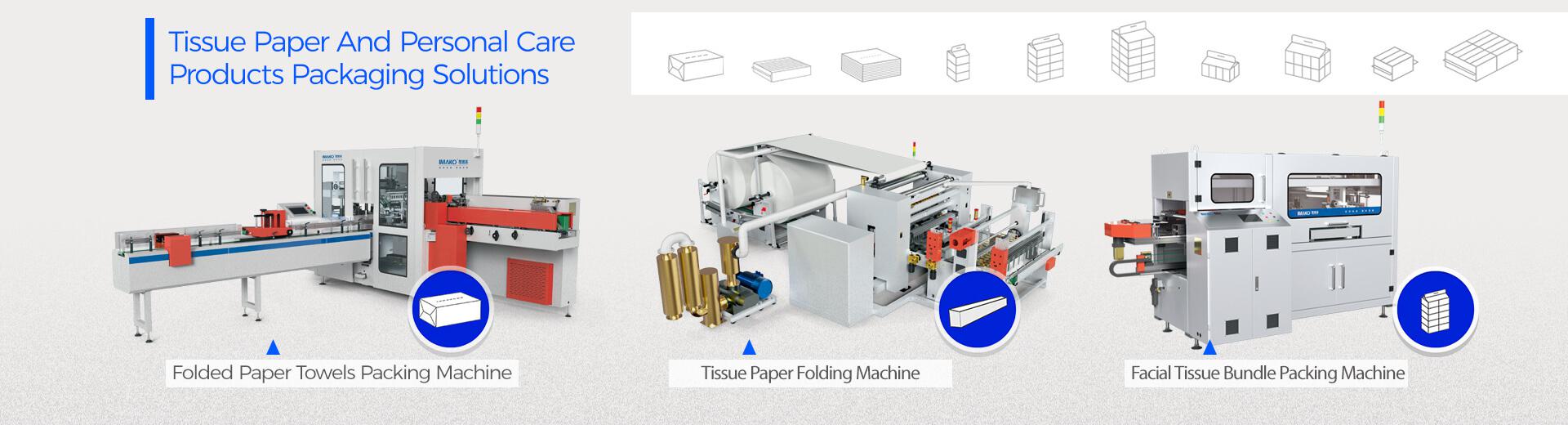

1. Components of Toilet Paper Manufacturing Machines. 2. Working Principles of Toilet Paper Manufacturing Machines. 3. Maintenance and Safety Considerations....

Introduction. 1. Regular Maintenance and Upkeep. 2. Proper Training and Skill Development. 3. Waste Reduction and Recycling. Conclusion....

1. Commercial Use. 2. Household Use. 3. Industrial Applications....

1,Toilet paper manufacturing machin applications Toilet paper manufacturing machine is a device used to produce toilet paper rolls. It is widely used in vari...

The creation of toilet paper is one of the most important inventions in the history of personal hygiene. Toilet paper making machines have made it easier for manufacturers to produce to...

Toilet paper is an essential item in our daily lives, and it's hard to imagine a world without it. Have you ever wondered how toilet paper is made and where it comes from? Well, in this...

Main performance and structure features 1. Double transducer control, easy maintained, decreasing abrasion with long life. 2. human-machine operation, convenient and quick parame...

Advantages of Wet Wipe Roll Film Packing Machine A. High efficiency and speed B. Consistent product quality C. Hygienic packaging D. Reduced labor costs E. User-friendly operation...

Paper Products Manufacturing: Toilet roll bundlers are used to package individual toilet rolls into convenient packages for distribution and sale. toilet roll bundlers are used to imp...