![]() Price: Negotiable

Price: Negotiable

![]() Model Number: TP-B35TE toilet paper maker

Model Number: TP-B35TE toilet paper maker

![]() Power: 20.6KW

Power: 20.6KW

![]() Application: Single Soft Packed Facial Tissue, Hand Towel Paper Napkin

Application: Single Soft Packed Facial Tissue, Hand Towel Paper Napkin

![]() Weight: 6500KG

Weight: 6500KG

![]() Output: 25 Packs/Minute

Output: 25 Packs/Minute

![]() Packaging dimension: Length (L): 240-450 Width (W): 120-420 Height (H): 90-270 MM

Packaging dimension: Length (L): 240-450 Width (W): 120-420 Height (H): 90-270 MM

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

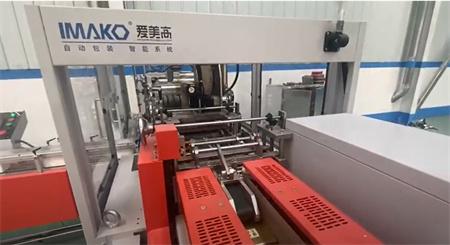

![]() Brand Name: IMAKO

Brand Name: IMAKO

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET

![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port

![]() Delivery Time: 90 Days

Delivery Time: 90 Days

![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

★ Adopts servos control for tissue arrangement, counting, stacking, tissue fill to bag, bag catching, bag conveying, bag opening and seal parts, This machine is easy to operation and maintenance.

★ Adopts central vacuum management mode, can efficiency lower power consumption.

★ Adopts intelligent sealing system, alternating current control, up & down independent temperature control, can meet different kinds of packaging materials, ensure nice sealing and stably running.

★ The machine is suitable for bundle packing 1-3 rows and 1-3 layers, easy to change specification and maintenance, high efficiency.

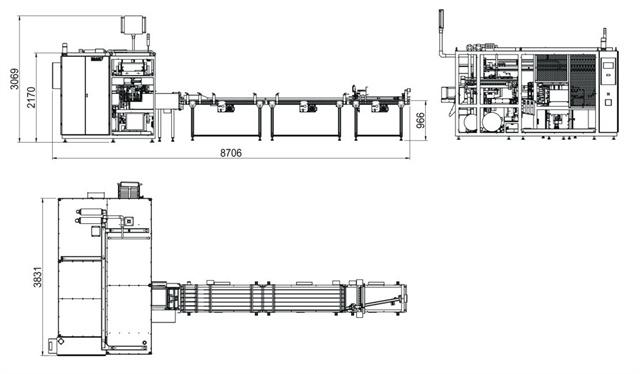

|

TP-B35TE main parameter configuration |

||

|

Specification/Model/ item |

TP-B35TE |

|

|

Scope of application |

Single packed tissue to bundle packing |

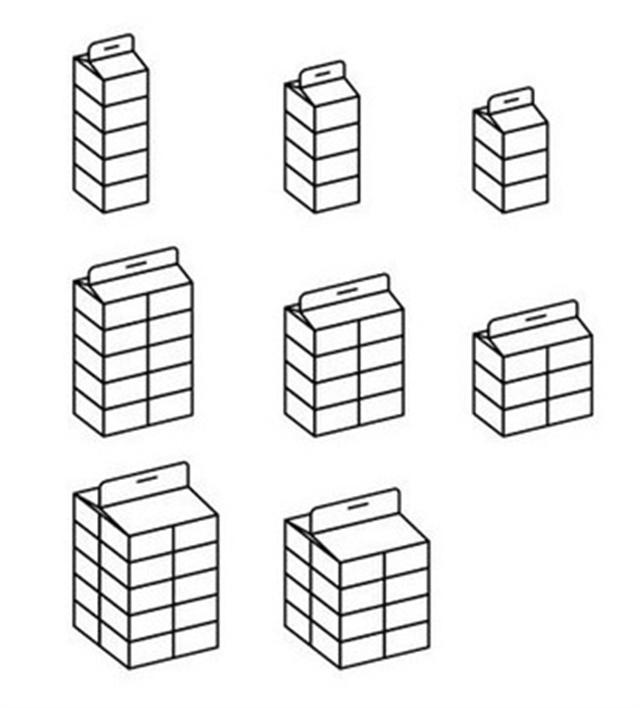

Packing styles |

|

Feeding mode |

Horizontal feeding |

|

|

Packing styles (Layer x row x column) |

One Layer 1x(1-3x(3-5) Two layers 2x(2-3x(3-5) three layers 3x(2-3x3-5) |

According to single pack size |

|

Design speed |

25 packs/minute |

|

|

Stable speed |

≤20 packs/minute |

Relate to product size |

|

Bag install mode |

Dual bag racks |

|

|

Bag rack storage Qty |

≤600 pcs prebags |

|

|

Single packed tissue range(mm) |

L120-210 / W90-110/H60-100 |

|

|

Machine weight (KG) |

6500 |

|

|

Bag type |

CPP、PE |

Thickness:0.05mm |

|

Compressed air(MPA) |

Press 0.6mpa flow 30Lmin |

|

|

Power supply |

380V/50HZ |

|

|

Machine movement control mode |

16 shafts servo positioning control |

Servo control |

|

Machine main transmission mode |

Servo motors drive,belts transmission |

|

|

Machine color and craft |

Deep grey.static spray plaint craft |

|

|

Bag type |

Same to manually packing |

Air hole≤2.5mm |

|

Gusset forming mode |

Vacuum mold forming |

|

The Facial tissue paper making machine has become an essential part of modern society. With the growing demand for hygiene and convenience, the use of tissue paper has increased exponentially. Tissue paper making machines are designed to produce high-quality tissue paper for various purposes, such as facial tissue, toilet paper, and napkins.

The history of tissue paper dates back to the 6th century in China, where it was first produced using mulberry bark. It wasn't until the 19th century that tissue paper became widely available in Europe and North America. The first tissue paper making machine was invented by the Fourdrinier brothers in England in the early 1800s. Since then, tissue paper making machines have undergone many advancements, improving its efficiency and output.

The tissue paper making machine works by converting a pulp mixture into a long sheet of tissue paper. First, wood pulp or recycled paper is mixed with water to create a pulp mixture. The pulp mixture is then fed into the machine, which spreads it evenly across a wire mesh screen. The excess water is drained off, and the remaining pulp is pressed and dried to create the final product.

There are two types of tissue paper making machines: single ply and double ply. Single ply machines produce one layer of tissue paper, while double ply machines can produce two layers simultaneously. Single ply machines are more common and produce tissue paper that is used in napkins, facial tissue, and toilet paper. Double ply machines produce thicker tissue paper that is used in industrial applications, such as paper towels and wipes.

In conclusion, the tissue paper making machine plays an important role in meeting the ever-growing demand for tissue paper products. With new innovations and advancements in technology, tissue paper making machines will continue to improve in efficiency and output. It is essential to invest in the latest and most advanced tissue paper making machines to continue producing high-quality tissue paper products that meet the demands of modern society.

There was a time when people used leaves, mud, and even stones to clean themselves after using the washroom. However, with industrialization and advancements in technology, the production of toilet paper has become a multi-billion-dollar industry. This article aims to provide an insight into the world of toilet paper makers.

The use of paper for sanitary purposes can be traced back to as early as the 6th century AD in China. However, the invention of modern toilet paper can be credited to Joseph Gayetty, an American, who created the first commercially-sold toilet paper in 1857. It was not until the late 19th century that toilet paper became more widespread and affordable thanks to mass production.

The production of toilet paper starts with the selection of raw materials comprising of pulp and recycled paper. The combination of both is important in achieving the desired strength and softness. The paper is then put through a series of processes including bleaching, softening, and drying. Once the finished product is ready, it is rolled into large reels which are then cut into the familiar small toilet paper rolls you see in stores.

While toilet paper is a necessity, the production process has significant environmental implications. The cutting down of trees for pulp leads to deforestation, whereas the use of chemicals during the bleaching process affects water quality. As such, many toilet paper makers have adopted eco-friendly practices such as tree planting initiatives, using recycled materials, and reducing water usage during production.

In conclusion, toilet paper may be something we take for granted, but its production requires sophisticated machinery, skilled labor, and a lot of resources. It is also crucial for us to consider the environmental impact of this product and support companies that have adopted sustainable practices. Who would have thought that something as simple as toilet paper could have such a significant impact?

1.TP-T450A multi servo high spped facial tissue single wrapping machine is suitable for automatically packing facial tissue paper, V fold wipes, napkins or similar Non-woven fabric, dus...

Toilet paper, as an essential consumer product, has become a necessity in daily life. The production of toilet paper is undertaken by a type of machinery known as atoilet paper maker. I...

The toilet paper roll manufacturing machine is an essential piece of equipment in the production of toilet paper rolls. It has revolutionized the toilet paper industry by making it poss...

pIntroduction:/p Toilet tissue making machines are crucial in the production of toilet rolls that are widely used in homes, offices, and public facilities. These machines are designed t...

Ava

2024-06-06

Hunter

2024-06-06

Mila

2024-06-06

Nora

2024-06-06

Addison

2024-06-06